Satisfying the global demand for quality goods means that automation and improved monitoring of all processes are essential for international shipping. The global market for IT tools for logistics offers comprehensive solutions to meet these needs. Nowadays, freight carriers and shippers around the world can get the most precise data on the location of a shipping container anywhere in the world, among other advanced features discussed in this article.

What is the meaning of container tracking?

Container tracking includes a set of measures aimed at providing all parties to the logistics process with detailed information about the container's location, transportation status, shipping route, and relevant events. Ship tracking and cargo monitoring involve processing a huge amount of data from shipping lines and logistics providers for a particular shipment. These are mandatory measures during the transportation process that safeguard your investment and help to avoid missing containers, delayed delivery, and other supply chain risks you should be prepared for.

How does the shipping container system work?

AIS system

To track a container vessel, the Automatic Identification System is used to automatically identify it with related data. The International Maritime Organization has standardized the use of AIS tracking for international shipping to facilitate and optimize shipment tracking and ensure maritime traffic safety.

Utilizing AIS data, logistics process parties can get advanced vessel data (including vessel type, length, name, and IMO), real-time container location, route information (including cargo type, destination, and estimated time of arrival), and more.

The financial and time commitment required to track ships was necessary before AIS technology became widespread. These AIS receivers instantly pick up radio waves provided by other AIS transmitter devices on ships. Thus, the location of containers and other data is instantly indicated in real-time. Additionally, the global positioning system (GPS) enhances visibility by providing real-time location data of containers, enabling effective monitoring satellite tracking and management of cargo movements.

Container Tracking Devices (CTDs)

CTDs are one more way to track the location of a container, but they have significant disadvantages compared to the strength of the AIS system. GPS tracking devices, with advanced geofencing capabilities, offer features such as setting up virtual boundaries and notifications for unauthorized movements, addressing the complexities and challenges associated with container tracking device solutions.

For reasons of economy and convenience in organizing and carrying out cargo transportation, the SeaRates team does not recommend using Container Tracking Devices. Among the disadvantages of CTDs are the following:

- Each devices has a very limited charging capacity (about 3 months);

- CTDs are vulnerable and require uninterrupted coverage, and in case of access point fluctuations, they interrupt data transmission;

- CTDs do not display or transmit data on container damage or loss;

- CTDs need to be manually attached to the outside of each container individually, which is not convenient for international transportation.

How to track a container?

Nowadays, the ways to locate a cargo container are simple and fast. It is enough to have information that identifies a specific container.

Sea freight is tracked using the container, bill of lading, or booking numbers, while air freight is tracked with Tracking ID and Air Waybill.

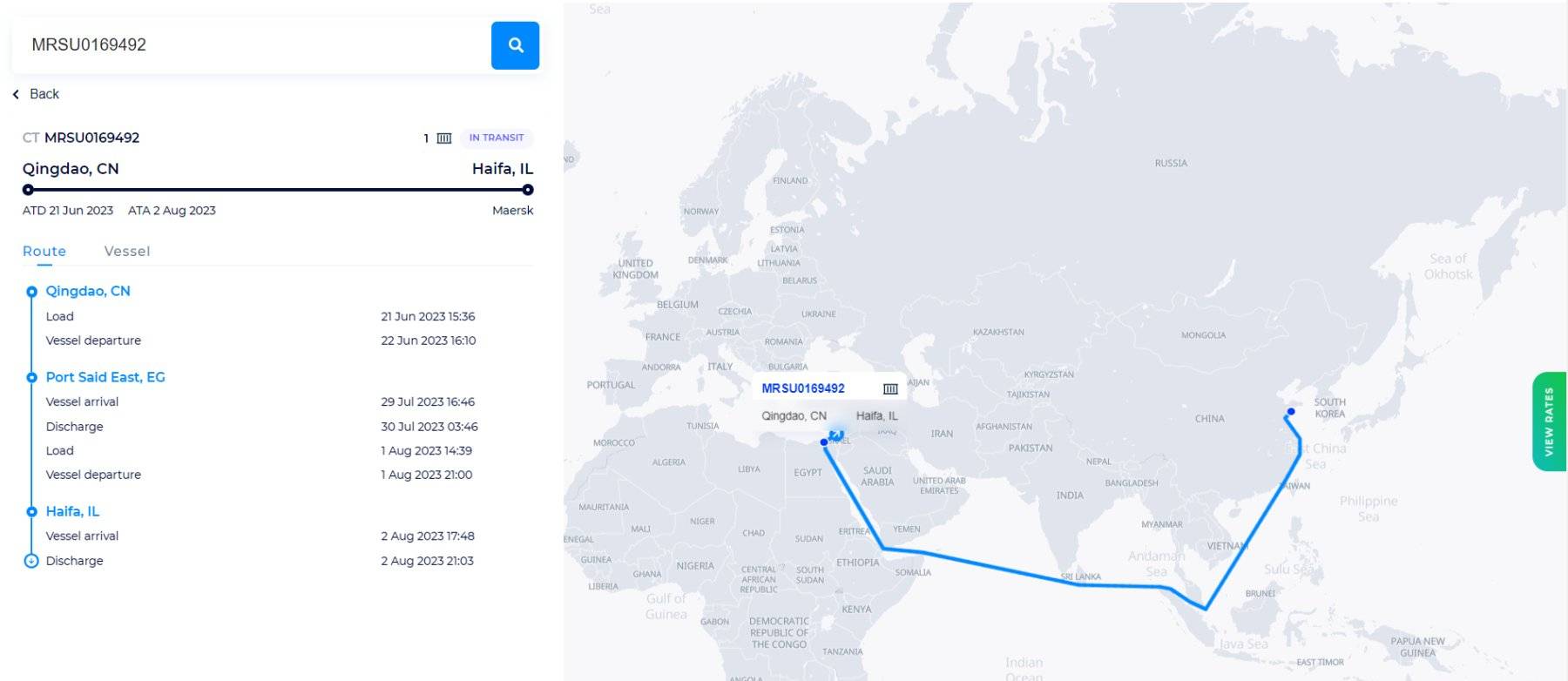

Let us analyze how shipping containers get tracked using examples:

Container Number (CT)

The container number, assigned by the carrier, is comprised of four letters and seven digits, each carrying specific information:

- The first three letters signify the owner.

- The fourth letter indicates the category of equipment.

- The container owner determines the six-digit serial number.

- The last digit serves as a validity check for the entire number.

Based on the container number, the shipper, carrier, and other parties in the supply chain can track the current location of the container, obtain the estimated date and time of arrival and departure from the port, and so on.

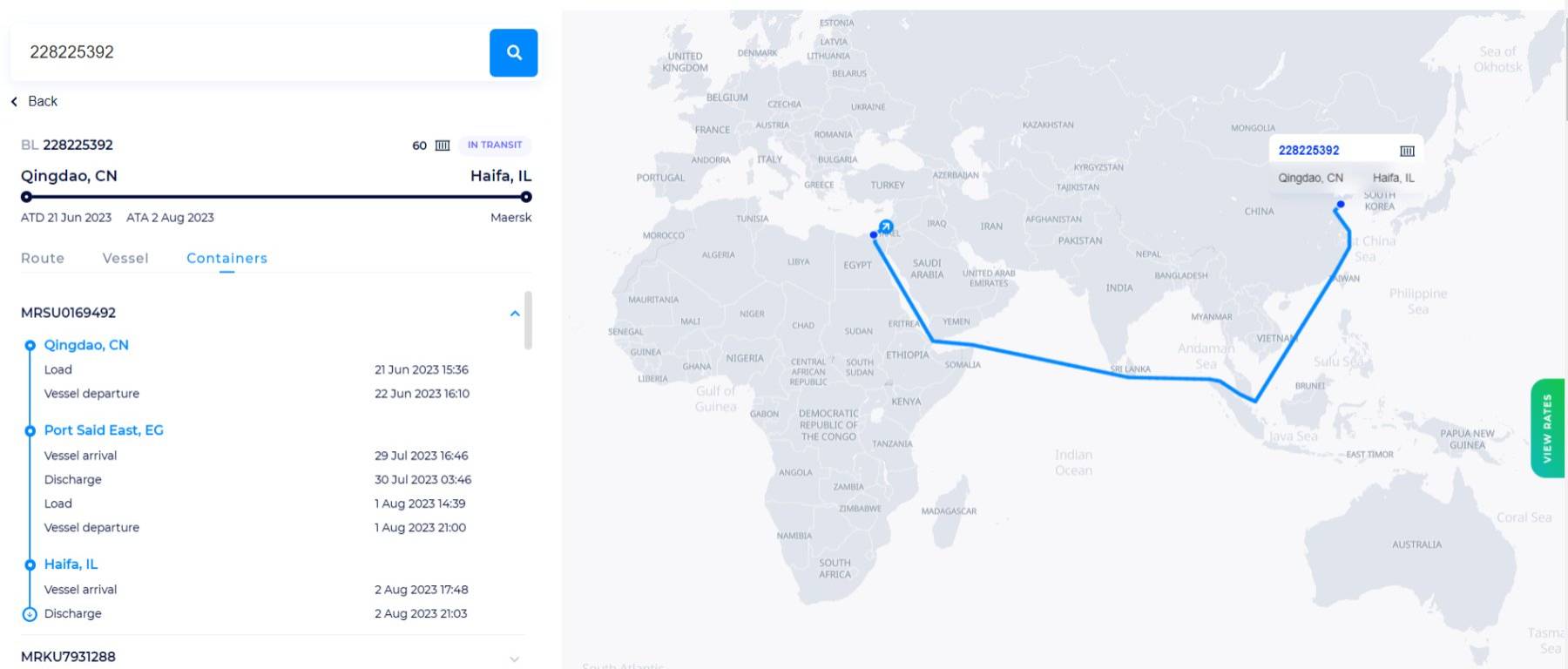

Bill of Lading (BL)

A document such as a bill of lading is created to confirm the cargo's rights and keep all its details. The bill of lading is also a legal confirmation of the cargo transportation agreement between the carrier, shipper, and consignee. Learn about the value of a bill of lading and its differences from a sea waybill in our guides.

The bill of lading data is marked with an identification number, which can also be used to track the cargo. The bill of lading number is assigned to the numbers of several containers that can be tracked separately.

Booking Number (BK)

Shipping companies provide shippers with a booking number generated by their individual vessel space booking system. A group of containers can also be tracked by a booking number.

Tracking ID

Air shipments are tracked by unique codes (numbers), such as Tracking ID and Air Waybill.

When transporting parcels by air, the carrier assigns a Tracking ID, which is used to track the movement of the cargo and predict the delivery time.

Air Waybill (AWB)

The Air Waybill is a document attributed to the shipment to keep track of the parcel and its handling. The document contains data on the airport of departure and arrival, the declared value of the shipment (for customs procedures), a description of the package, and other details. The abbreviated Air Waybill code is used to track the movement of cargo from the airport of departure to the destination.

By tracking containers according to the above parameters, you can quickly respond to delays or losses of cargo throughout the entire delivery process. On carriers’ sites or platforms, each party in the supply chain can track and receive comprehensive data to plan their operations efficiently.

Tracking containers' status terms

To generate and manage data on the container shipping status and events recorded. The SeaRates team has provided below the meanings of logistics terms that describe changes and updates to the container's transportation status. The way containers are transported from the port of loading to the port of destination is as follows:

- POL - Port of Loading

- CEP - Container empty to shipper

- CPS - Container pickup at shipper

- CGI - Container arrival at first POL (Gate in)

- CLL - Container loaded at first POL

- VDL - Vessel departure from first POL

- ETD - Estimated Time of Departure

- ATD - Actual Time of Departure

- VAT - Vessel arrival at T/S port

- CDT - Container discharge at T/S port

- TSD - Transshipment Delay

- CLT - Container loaded at T/S port

- VDT - Vessel departure from T/S

- ETA - Estimated Time of Arrival

- ATA - Actual Time of Arrival

- POD - Port of Discharge

- VAD - Vessel arrival at final POD

- CDD - Container discharge at final POD

- CGO - Container departure from final POD (Gate out)

- CDC - Container delivery to consignee

- CER - Container empty return to depot

- LTS - Land transshipment

- BTS - Barge transshipment

For full management of Port-to-port or Door-to-door shipments, the above matters are essential for the timely planning of logistics operations. By receiving and sharing all shipping data through your platform, you ensure smooth cargo flow and transparent and convenient delivery to any destination. So how does the carrier get the time of arrival of the container at the port of destination and assure the consignee that the container will arrive on time?

Where to track my container?

Shipping lines' websites

Shipping companies are increasingly popularizing such a positive way of interacting with shippers as the "Tracking my shipments" option on their websites. Logistics providers use the advanced data from the SeaRates database to integrate the Tracking System widget into their websites. Shippers can quickly search for their shipments by container number. Thus, the demand for carrier services and customer interaction in the post-sale period increases.

Carriers and freight forwarders

Logistics providers get the opportunity to create their own unique tracking tool that visualizes transportation processes and simplifies supply chain operations. Advanced supply chain management is possible by quickly integrating the Tracking System API into your TMS, ERP, and CRM systems. Explore the possibilities of providing shipping data for your business on our Developer Portal.

SeaRates’ Tracking System

The above methods require separate data entries for container tracking. It is much more convenient to track your shipments on the SeaRates Tracking System, where containers are stored in your Profile to update shipping statuses quickly.

You can find the exact location of your shipping containers, all events, and additional information for supply chain management by container, bill of lading, and booking number in real-time.

This way, you will get acquainted with the functionality of the Tracking System tool Version 3, which works with updated data from 160+ carriers (including major shipping lines, the most trusted NVOCCs, and key market operators around the world).

Conclusion

For any business, cargo transportation operations need to be transparent and reliable. You will not incur additional expenses due to cargo delays if you rely only on highly accurate shipping data.

The SeaRates team empowers logistics providers and other parties in the supply chain to collect and utilize real-time precise data on the status of any type of shipment.

Contact us at [email protected] to integrate the SeaRates Tracking System tool into your business processes.

Explore more opportunities with SeaRates by [contacting us] respective to your interest category