Pallet shipping is an indispensable part of modern logistics and supply chains. It involves the use of pallets to transport goods efficiently and securely from one point to another. With the growing demands of global trade, pallet shipping has become a crucial aspect for businesses to ensure that their products reach customers in a timely and safe manner.

Pallet shipping is a critical logistical process for many businesses. But it can be complex and challenging, especially if you're not an expert. In this article, we'll share tips for mastering pallet shipping and achieving logistical efficiency and safety.

Key Components of Pallet Shipping

Choosing the proper size

The choice of pallet size should be based on the type of goods, their destination, and your loading and unloading preferences. Following that, it's advisable to take into account the dimensions of the warehouse and transport. The International Organization for Standardization (ISO) recognizes six distinct pallet dimensions, each associated primarily with a specific region of use.

| Region | Dimensions in inches | Dimensions in millimeters | Unused Area in a Standard 40′ ISO Container |

| Asia | 43.3 x 43.3 | 1100 x 1100 | 14% |

| Australia | 45.9 x 45.9 | 1165 x 1165 | 8.1% |

| Europe | 31.5 x 47.24 | 800 x 1200 | 15.2% |

| Europe, Asia | 39.27 x 47.24 | 1000 x 1200 | 8.1% |

| North America | 40 x 48 | 1016 x 1219 | 3.7% |

| North America, Europe, Asia | 42 x 42 | 1067 x 1067 | 11.5% |

After selecting the type of pallet, you can consider their size when planning the loading of the container. The Load Calculator tool has a special checkbox that allows you to add pallets to the packing layout. You can also find out more about other pallet sizes and container placement options by exploring this reference.

The most common materials for pallets

- Wood Pallet. Standard in dimensions and with four-way entry capabilities, these pallets can be designed to carry either heavy or light loads. They are crafted to support the full weight of the packaged product, withstand the rigors of the shipping environment, and ensure adequate top board spacing to avoid forklift blade impact. This type of pallet dominates ocean transportation. Typically, they weigh from 15 to 18 kg.

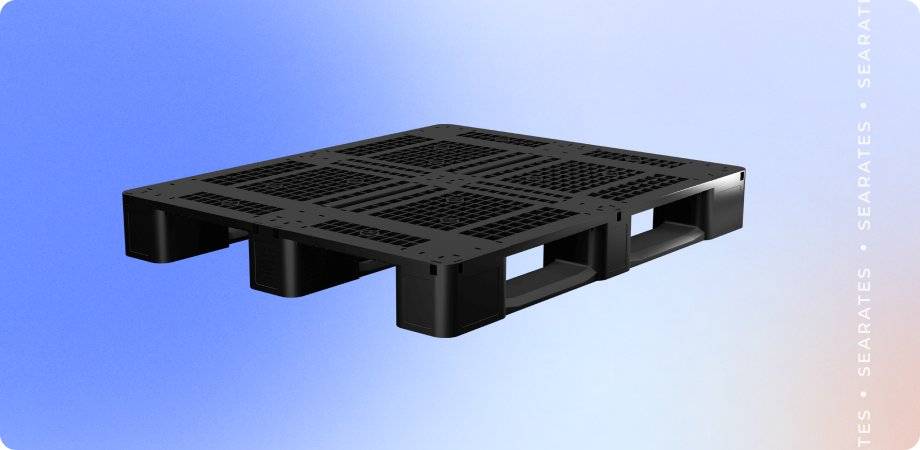

- Plastic Pallets. These are usually pricier and heavier than wood pallets (up to 30-40 kg), but are reusable. They are sometimes designed with a solid deck, which protects the package bottom from forklift tine damage during loading and unloading.

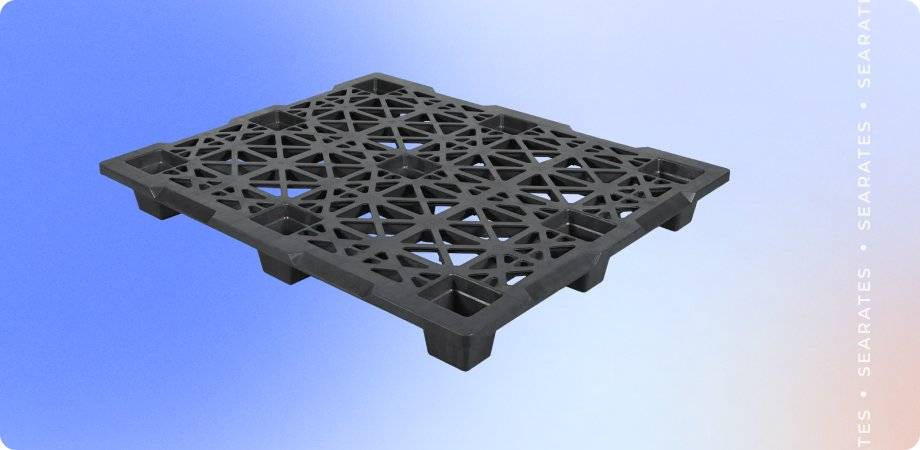

For lighter loads, lightweight (5-10 kg) plastic pallets can be used. They are much cheaper, but not very robust, making them non-reusable and less environmentally friendly.

For lighter loads, lightweight (5-10 kg) plastic pallets can be used. They are much cheaper, but not very robust, making them non-reusable and less environmentally friendly.

- Cardboard Pallets. Also known as corrugated fiberboard pallets, they are not recommended as they are easily damaged, especially susceptible to moisture damage, and often not reusable. But they can be useful for transporting light, dry cargo. They are well suited for air transport, where lightness is a critical factor, as they weigh less than 4 kg.

- Pressed Pallets. Available as pressed block-style pallets and molded pulp pallets. Both weigh approximately 15 kg in standard dimensions. Cheaper than wooden ones, but suitable only for light loads and can handle only a few shipments.

Safe shipping through proper palletizing

- Start with wrapping. Start by winding high-quality shrink wrap through the inner area of the pallet and around its top layer multiple times, twisting the wrap to enhance its strength. Ensure you've left adequate space for forklift access. Don’t sever the stretch-wrap yet; keep it on standby for post-stacking.

- Lay the foundation. Place a flat cardboard slip sheet beneath the load and between layers to evenly distribute weight and firm up loose boxes. This lays a solid foundation for stacking.

- Box arrangement. Stack your boxes starting with the heaviest at the bottom, aligning them in columns, corner-to-corner on the pallet, for optimal stacking strength. Steer clear of irregular or interlocking layer patterns, which can compromise stability.

- Avoid the ‘pyramid’ load. Resist the urge to create a pyramid; instead, keep removing packages to ensure a flat top layer. This will avert any damage from top loads and ensure stability during transit.

- Mind the edges. Boxes should remain within the confines of the pallet edges to prevent crushing. A lack of uniformity in container sizes could result in inadequate support during transit.

- Beware of the gaps. Never align box corners with the gaps between pallet boards, as it can cause instability and potential damage from forklift handling.

- Corner-boards for strength. Employ cardboard corner-boards at every corner of the shipment, and cap it off with a final cardboard slip sheet on top for added fortification.

- Final wrapping. Use the set-aside stretch-wrap to envelop the shipment, making at least five revolutions in each direction to keep items together. Twisting the wrap adds extra strength.

- Strapping for security. Assess if your shipment needs additional stability or protection. Utilize bands or nylon straps to anchor it down if necessary, threading them through the pallet's center.

- Labeling and documentation. Affix the appropriate labels to your shipment and include all required documentation to ensure a smooth delivery via transit points.