During the 20th century, the handling and carriage systems of cargo by rail, road, and sea were dramatically changed by the advent of containers.

Containerization was first introduced in the 30s' by Malcolm McLean—later the founder of SeaLand—and developed as part of military logistics during World War II.

At first, the new system focused on the vital need to speed up land and sea transport, as well as the loading and discharging of standardized cargo units.

Later on, the new transport system proved that, in commercial terms, it could also help to drastically reduce the handling and packing costs and significantly curb pilferage and damage to cargo.

In the beginning, the dimensions of the containers were 20'x8'x8' and 40'x8'x8', but within a few years, the present sizes of 20'x8'x8,6' and 40'x8'x8,6' were generally adopted worldwide, providing larger cargo-carrying capacity, i.e., 33 CBM for 20' and 66 CBM for 40' containers.

Container dimensions and the relevant allowances are established by the International Organization for Standardization (ISO) worldwide as follows:

- 20'ext.width mm 2.438 +/-5 mm ext.height mm 2.591 +/-5 mm ext.length mm 6,058 +/-5 mm.

- 40'ext.width mm 2.438 +/-5 mm, ext.height mm 2.591 +/-5 mm, ext.length mm 12.192 +/-5 mm.

The maximum payload, together with the maximum gross and net weights, is indicated on the front side of each unit.

With a view to ensuring the best possible use of the container's internal space, the dimensions of such packages as pallets, cartons, crates, etc. must necessarily be sub-multiples of the container's dimensions.

All containers are marked with a container prefix of four letters and six digits (the container serial number). Generally, 20-foot containers are countersigned by 2 as the initial digit and 40-foot by 4.

A seventh digit, separately marked, called the check digit, is used to check, if necessary, whether the serial number is correct or not. The container tare is generally about 2 t. for 20' and 4 t. for 40’ containers.

Containers may be piled up on top of one another and must therefore be built so as to support a very heavy weight. They are mostly made of steel, which also serves to limit the damage caused by improper handling, particularly during loading and discharging operations.

Aluminum and plywood-made containers were introduced for a certain period to reduce tare weight, but since the losses far outweighed the gains, they have been withdrawn from service.

In addition to a normal dry van or general cargo container, the following special equipment is available for different purposes:

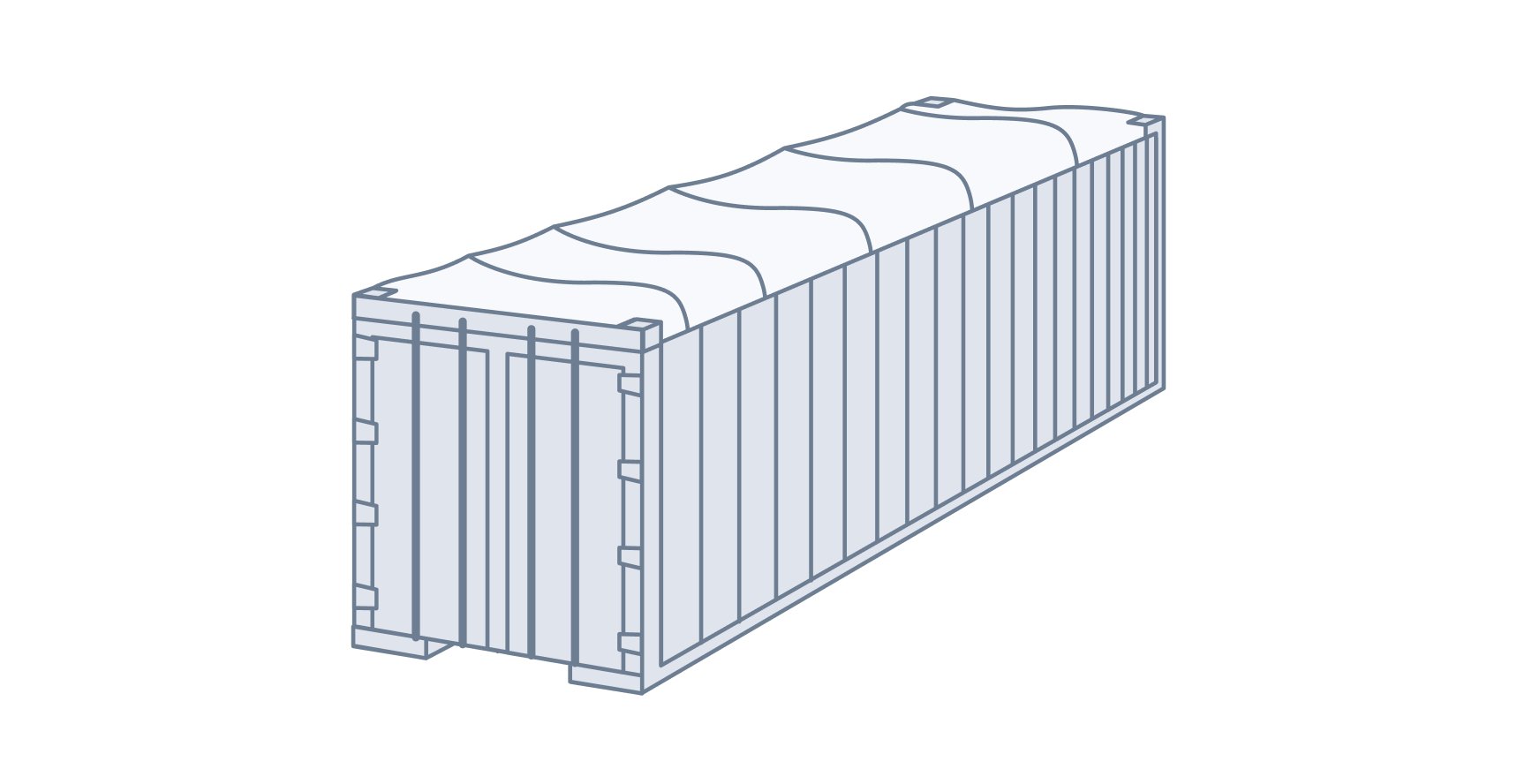

- 20' and 40' open-top units loadable from the top side, which may be covered by a tarpaulin fastened with a sealed cord;

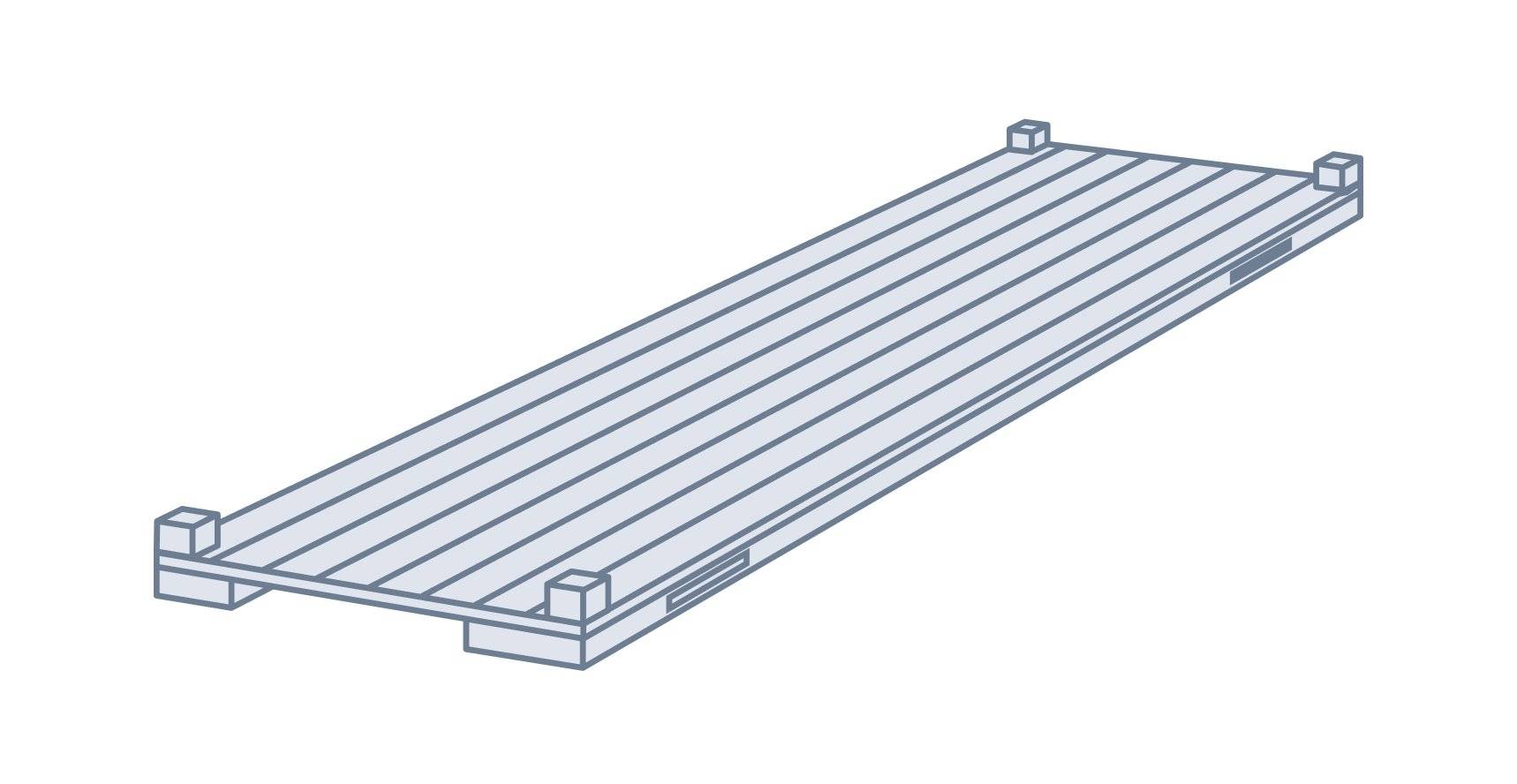

- platform containers used for out of gauge (oversize) cargo;

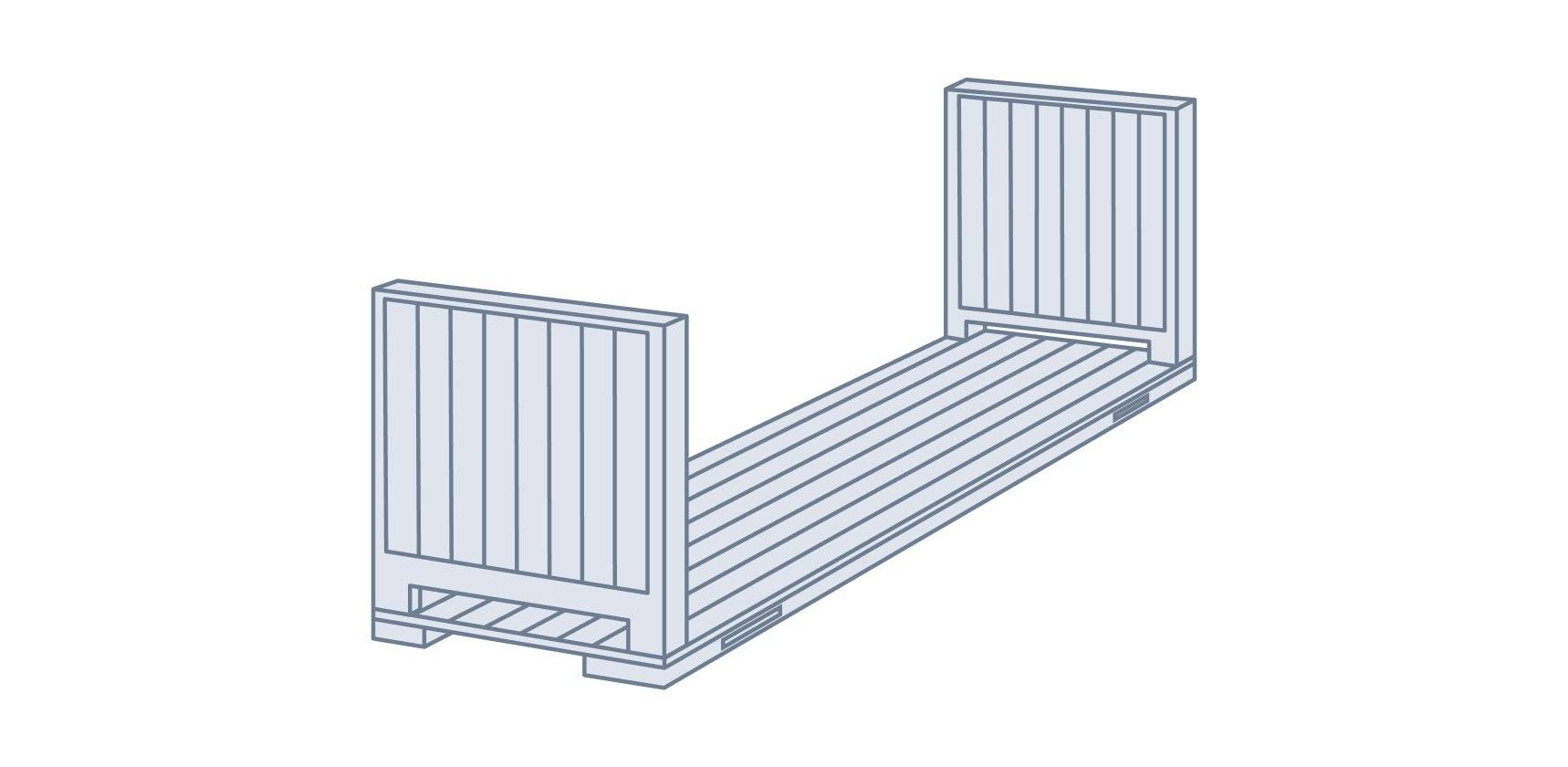

- flat racks with fixed or collapsible sides; Flat racks with collapsible sides can be over-stacked, one on top of another, thus taking up less space when they are repositioned;

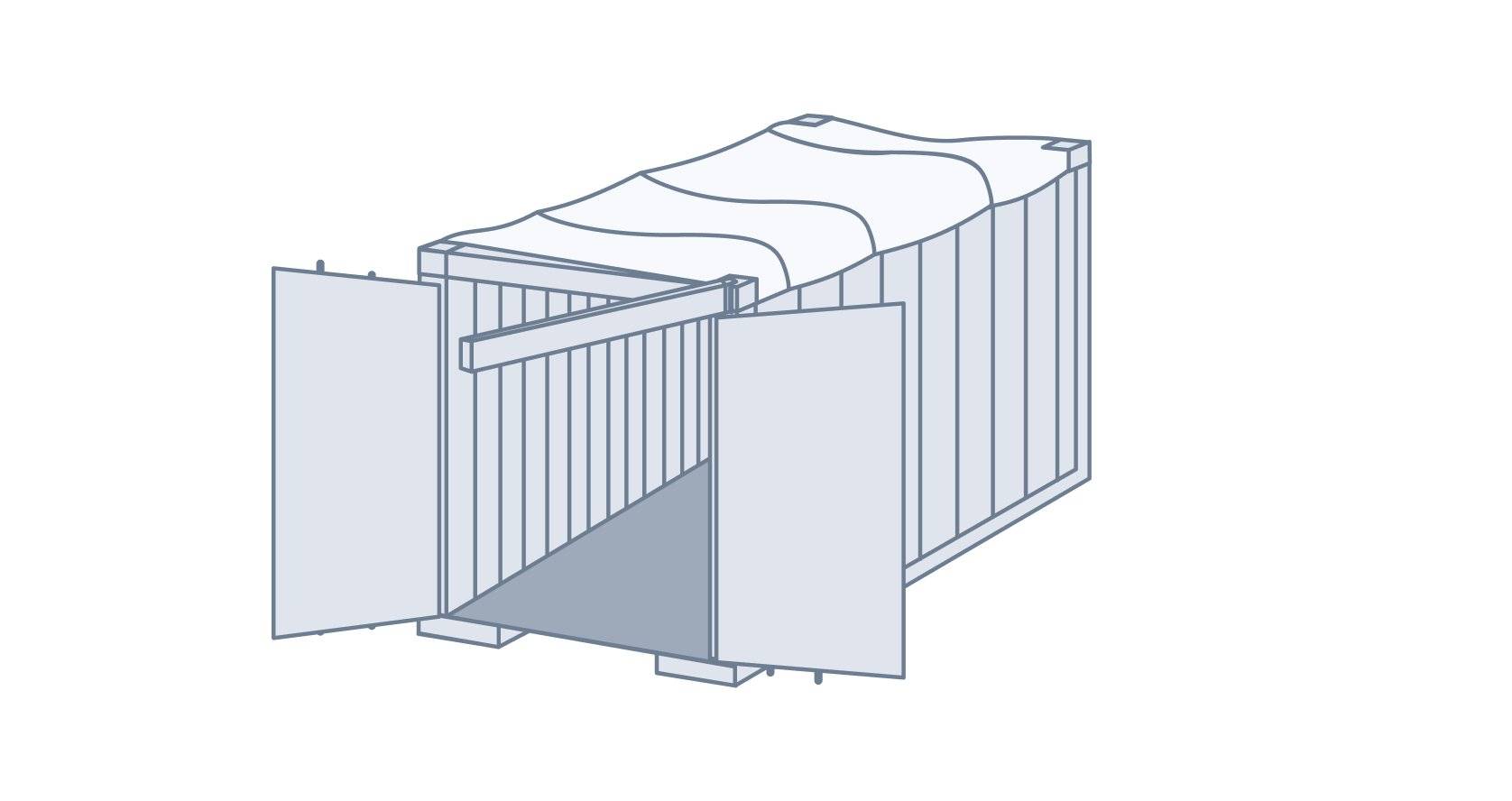

- 20' open-top fitted with a movable crossbar over the front-side door to facilitate the loading of out-of-gauge cargo;

- tank containers which, as a rule, belong to private concerns specializing in the carriage of liquid cargoes;

- reefer containers for the carriage of cargo at a controlled temperature;

- heavy payloaders: 20' units with a payload capacity of 27 tons;

- high cube: 40' containers of 9'6" in height (inside volume of 76 CBM);

- 45' containers - at present used only in certain trades and normally not meant for shipment in standard full-container vessels.

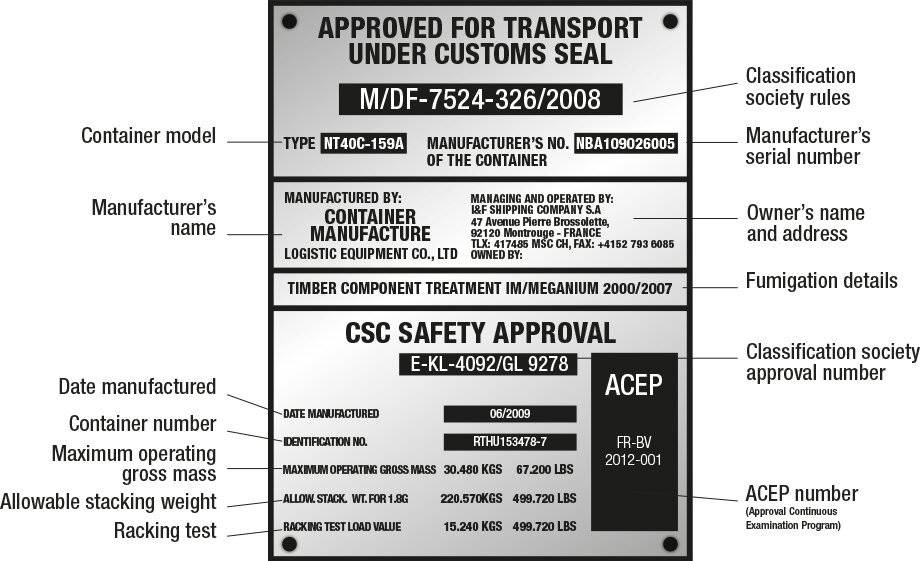

Understanding the CSC Plate of Shipping Containers

Containers are, in all respects, parts of the ship; a full-container ship without any containers on board is, in fact, just an empty hull. Their structure must therefore be strong enough to permit over stowage in numerous tiers of 20' units of 24 tons each. The allowed stacking weight of each unit varies according to its construction specification and is shown on the specific identifying C.S.C. plate.

Being part of the carrying ship, all units must be checked and approved by a classification society, which releases an identification plate-named "CSC" (Container Safety Convention) Safety Approval)-to be affixed to one of the doors of each unit.

The CSC plate shows, in addition to other details:

- the construction date;

- the unit's identification number;

- the greatest possible gross weight;

- the allowed stacking weight (the weight of the containers in a vertical column);

- the value of the racking test load;

- the due date of the "first maintenance examination".

All indications shown must be observed, and the unit may not be used if the CSC plate is missing.

All you need to know about reefer containers

Reefer containers (usually referred to as "reefers") deserve special comments. Reefers are quite expensive, and proper organization is required to ensure their continuous full efficiency. In fact, "reefers" are fitted with an electrical refrigerating device that must be permanently connected to a generator. This is possible in the case of road transport.

However, "reefers" cannot be carried by rail since there are no generators available on rail wagons.

The cargo stuffed into reefers is usually quite valuable. The carrier must therefore ensure that when the empty unit is positioned for stuffing, the inner temperature is already the one indicated by the shipper.

In fact, it takes some time, particularly during the summer, before it reaches the prescribed temperature. This can range between + 2° and + 4° Celsius for fresh fruit, and between 18° and -22° for refrigerated meat or other cargoes.

A "reefer" that isn't the right temperature to use for stuffing could actually harm the goods inside.

Once stuffed, reefers must maintain the required temperature at all times. Because they need to be plugged in at all times, including when they are being transported on land, at the container terminals of the ports where they are going and coming from, and, of course, when they are being transported by sea.

A special device, the thermographic disc, records at regular intervals the inner temperature of the reefer. There is a way to figure out who is to blame for any problems with electricity at any point in the transportation of goods.

To be sure, the temperature scale (Fahrenheit or Celsius) the shipper has chosen must be shown in the cargo manifest. This must also be done.

All ships have enough electric plugs so that reefers can be connected right away when they are loaded.

During navigation, the ship's staff must carry out the prescribed checks and any necessary repairs to the refrigerated device. Refrigerated cargo is, by the way, a very high-paying cargo.

By no means, however, should a clause involving any commitment on the part of the carrier to guarantee the maintenance of the temperature required by the shipper throughout the entire carriage by land and sea be shown in the bill of lading. Any clause like this would be very risky for the ship's owner, because there are a lot of things that need electricity on a ship.